Iron processing Ores, Smelting, Refining Britannica

Most iron ores are extracted by surface mining Some underground mines do exist, but, wherever possible, surface mining is preferred because it is cheaper Lumps and fines The deep mining of iron ore is unusual in the modern era, but in northern Sweden, ore is mined from considerable depth largely aided by the application of Iron ore extraction techniques ScienceDirect

Life cycle assessment of iron ore mining and processing

The extraction of iron ore involves surface (openpit) or underground mining techniques (please refer to Chapter 7 (Stace, 2015) on Iron Ore Extraction Abstract Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate In this paper, iron recovery from IOTs was studied at different points during a Minerals Free FullText Recovering Iron from Iron

The Extraction of Iron Chemistry LibreTexts

The Extraction of Iron This page looks at the use of the Blast Furnace in the extraction of iron from iron ore, and the conversion of the raw iron from the furnace into various This work has demonstrated that the reductive dissolution of a widespread ferric iron mineral, goethite, catalyzed by acidophilic microorganisms, can be an effective method of extracting metals from A New Direction for Biomining: Extraction of Metals by

Monitoring of Iron Ore Quality through UltraSpectral

Currently, one of the main ways to evaluate the quality of iron ore produced at any stage of the production chain of mining companies is through chemical analysis methodologies of samples, which are Biomining, the biotechnology that uses microorganisms to extract metals from ores and concentrates, is currently used exclusively for processing reduced ores and mine wastes Metals of economic value A New Direction for Biomining: Extraction of Metals

The Extraction of Iron (GCSE Chemistry) YouTube

This video aimed at GCSE students, describes how iron can be extracted from iron ore in a blast furnace The Extraction of Iron (GCSE Chemistry) 72,655 views 72K views In this study, a novel technology for the comprehensive utilization of lowgrade iron ore is presented For the iron ore with a Fe content of 2491%, a pilotscale study of preconcentration, suspension Novel Technology for Comprehensive Utilization of

The Planet Crafter Ore Extractor Guide TechRaptor

If you intend to automatically make Super Alloy Rods with an AutoCrafter, you will need an additional Ore Extractor T3 dedicated to Aluminum a Super Alloy Rod costs 8 Super Alloy and 1 Aluminum Uranium 5 Iron (and the base materials) are always useful Iridium is needed for building more Heating objectsIron ore crushers and other machines There are several ways to extract iron ore from rock Here is a basic flow chart outlining the steps involved in the production of iron from iron ore: MiningHow to extract iron ore flow chart? LinkedIn

WOA1 Extraction of iron (iii) oxide from different iron

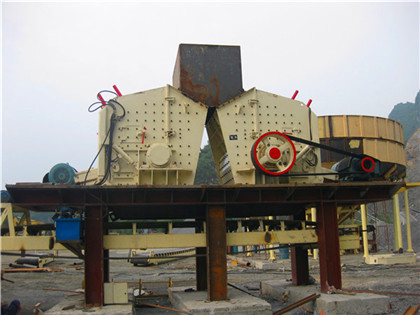

A method of extraction of pure iron (III) oxide from bulk iron ore is provided that includes crushing and grinding, using a crushing machine, raw hematite ore, where a milled ore is formed, waterwashing the milled ore by rinsing under continuous stirring conditions, dilute acidwashing the milled ore with diluted hydrochloric acid under continuous stirring Once broken into smaller pieces, the charcoal and iron ore (sand) are mixed together in a 1:1 ratio 4 Charge the furnace Before adding the iron ore and charcoal mixture, the furnace must be charged Charging a furnace simply means heating it up to temperatures high enough for smelting to occurHow to Smelt Iron: The 6 Steps to Iron Smelting The Crucible

Life cycle assessment of iron ore mining and processing

The extraction of iron ore involves surface (openpit) or underground mining techniques (please refer to Chapter 7 (Stace, 2014) on Iron Ore Extraction Techniques)The LCA boundary used in this study is shown in Fig 214The mining method selected depends on a variety of factors, including the nature and location of the deposit, The article presents the history of iron ore mining and production in presentday Poland and takes into account mining and production techniques and the influence of mining on the development of the surrounding areas Examples of development are presented for the most important iron ore mining centers established since the Minerals Free FullText Historical Outline of Iron Mining and

Iron ore extraction techniques ScienceDirect

Iron ore was won by drilling and blasting (Fig 71)As mining technology generally developed, so did drilling techniques and the explosives used Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as “dogger”) allowing mine drivages to be selfsupporting However, he states This page looks at the use of the Blast Furnace in the extraction of iron from iron ore, and the conversion of the raw iron from the furnace into various kinds of steel Contributors and Attributions Jim Clark (Chemguidecouk) Prof Robert J Lancashire (The Department of Chemistry, University of the West Indies)The Extraction of Iron Chemistry LibreTexts

Deep Learning Approach at the Edge to Detect Iron

There is a constant risk of iron ore collapsing during its transfer between processing stages in beneficiation plants Existing instrumentation is not only expensive but also complex and challenging Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents overloading the crusher and increases its efficiencyThe six main steps of iron ore processing Multotec

Metals Free FullText Modeling Isothermal Reduction of Iron Ore

Iron ore pellet reduction experiments were performed with pure hydrogen (H2) and mixtures with carbon monoxide (CO) at different ratios For direct reduction processes that switch dynamically between reformed natural gas and hydrogen as the reductant, it is important to understand the effects of the transition on the oxide reduction Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together For this purpose, a travelinggrate machine is used, and the burning of fine coke (known as coke breeze) within the ore generates the necessary heat Before being delivered to the sinter machine, the ore mixture isIron processing Ores, Smelting, Refining Britannica

Iron Ore Mining The process of iron ore mining %y AtlamGroup

Iron ore mining is the process of extracting iron from its natural form, which is found in rocks and minerals The process begins by removing the topsoil from the area to be mined This soil is then replaced and compacted to make sure that there is no waterlogging or runoff The next step is to drill holes into the rock, so that explosives canWe’ve touched on iron ore’s presence in New Zealand and Nigeria already, but Iron ore makes up 5% of the Earth’s crust and is distributed all around the planet For instance, a mining and resource extraction company called BHP boasts 5 mines in the Pilbara region of Western Australia, though Rio Tinto is the largest mining company in this regionWhat The Heck Is Iron Ore? • Earth • Earthpedia

Database on Iron Ore Statistics Launched UNCTAD

The online Database replaces former printed publications of the Iron Ore Statistics, and is accessible upon subscription from the UNCTADSTAT portal A navigation browser allows table or graphic presentations, easy selection and reorganization of data, personalized functionalities and several straightforward extraction optionsThe Database The reduction of iron from its ores is a major sector inmetallurgical industry worldwide Suitable methods of extraction of iron from its ores have been a major concern since the nineteenth(PDF) An Overview of the ReductionSmelting Process of Iron

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

Shaking table, also called gold recovery table or gold separation table, is the best fine gold recovery equipment It can process both gold ore in quartz rock, gold stones, and placer gold The feeding particle size range of the shaking table is generally between 3mm0019mm The gold beneficiation is stable and reliable, and the distribution