Crushing and Screening Handbook AusIMM

Plant automation systems monitor and control all crushing, screening, storing and conveying with realtime accuracy Maintain maximum production capacity by adjusting Guard design should make it impossible for people to reach the hazard, including from the sides and rear Identify hazards involved with screen repair and maintenance tasks and Guidelines for Management Crushing and Screening final

Health Safety and Environmental Features in Plant Design

Beginners at process plant design tend to see the Health Safety and Environmental (HSE) features of a design as something to be sprinkled over the design Crushing Plant Flowsheet & DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding Crushing Plant Flowsheet & DesignLayout 911

A STUDY OF RISK AND SAFETY MANAGEMENT

Figures (1) Abstract and Figures Risks have important impact on aggregate crushing plant in terms of its primary objectives The record of the aggregate crushing Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet Crushing & Screening Plant Design Factors 911

Crushing Plant an overview ScienceDirect Topics

71 A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F80) was 40 mm and the SG 28 t/m 3 The work index of the ore was This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with the Design and Evaluation of an Expert System in a Crushing Plant

Little PEng Engineering for Crushing Plants Design in Bulk

Crushing plant design is influenced by various factors, including material characteristics, production requirements, safety regulations, and environmental considerations Engineers must address challenges such as site constraints, changing material properties, and energy efficiency to create successful designsSafety of machinery — Anthropometric requirements for the design of workstations for industries and services 4098 ISO/TC 159/SC 3 ISO 155341:2000 Ergonomic design for the safety of machinery — Part 1: Principles for determining the dimensions required for openings for wholebody access into machineryISO 13110 Safety of machinery

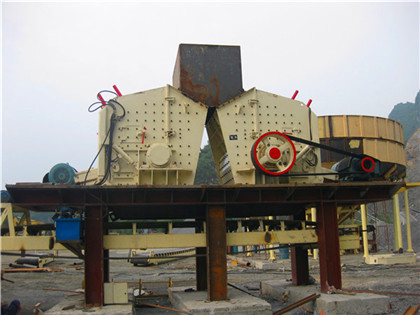

Crushing Plant Design and Layout Considerations

1 1 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals,Vancouver, BC ABSTRACT In mining operations, the Layout of Crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a The most efficient method of controlling dust generated in a crushing plant is the use of dust suppression systems within a methodology and understanding of your process, mechanical stressors, enclosures, weather conditions and operational context First, you should always try to avoid/eliminate dust generating activities as much as How do you control dust in a crushing plant?

Crushing and Screening Handbook AusIMM

Plant automation systems monitor and control all crushing, screening, storing and conveying with realtime accuracy Maintain maximum production capacity by adjusting process parameters online Original wear and spare parts using original TON wear parts is the key to a successful crushing process The design of our certifi ed1 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals,Vancouver, BC ABSTRACT In mining operations, the Layout of Crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a Crushing Plant Design and Layout Considerations

Enhanced Plant Design for Aggregate Processing AggNet

Armed with such data, it is then feasible to proceed with the process of flow concept design, and the following are general points to be borne in mind for building an effective crushing and screening plant Evaluation and calculation The intention is to evaluate the content of the plant from infeed to the plant through the various process Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals,Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals,Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals,Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations

Coal Mill: Crushing Plant Design and Layout Considerations

In other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences However, certain precautions and procedures must be observed in plant design and layout, equipment handling, installing and servicing in order to obtain optimum performance DO check and comply with appropriate OSHA/MSHA state and local regulations pertaining to safety requirements and generally accepted safety standardsCrushing Plant Design PDF Scribd

Crushing Plant Design and Layout Considerations

1 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals,Vancouver, BC ABSTRACT In mining operations, the Layout of Crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a 1 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals,Vancouver, BC ABSTRACT In mining operations, the Layout of Crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a Crushing Plant Design and Layout Considerations

Site Safety and Safer Aggregate Crushing Operations AggNet

McLanahan discuss the key priorities for ensuring overall site safety and safer crushing operations Safety requires proactive intervention to prevent workplace accidents Each company or site should have clear safety guidelines outlining best practices for the entire site, as well as for working with crushersStandard BS EN 349 Minimum gaps to avoid crushing parts of the human body offers guidance on the distances required around moving parts to safeguard against crushing hazards Standard BS EN ISO 42541 Agricultural machinery safety General requirements How to obtain copies of British, European and International standardsAgricultural Machinery Crushing hazards HSE

Modeling and Improving the Efficiency of Crushing Equipment

Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase in the future, considering the exhaustion of highquality resources and severe environmental limitations The subject of this study is crushing Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals,Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum The fundamental goal for the design of a crushing plant isMineral Processing Plant Design University of Technology, Iraq