Efficient flotation recovery of lead and zinc from refractory lead

Labscale experiments results show that the new process contributed to the flotation of the complex mixed sulfideoxide lead and zinc ore regarding two Labscale experiments results show that the new process contributed to the flotation of the complex mixed sulfideoxide lead and zinc ore regarding two Efficient flotation recovery of lead and zinc from

RCS™ flotation solutions TON global website

TON supplied 68 RCS flotation machines which have given better yield and improved results Installed plant with 15 MT capacity, which is achieving close to 2 MT now Result The aim of this paper is to develop an efficient flotation process to selectively separate zinc and lead from highoxidized lead zinc ore Firstly, the process Process Mineralogy Characteristics and Flotation Optimization of

Efficient flotation recovery of lead and zinc from refractory lead

Labscale experiments results show that the new process contributed to the flotation of the complex mixed sulfideoxide lead and zinc ore regarding two aspects: In the rougher flotation stage, a lead concentrate with 1729% Pb and a zinc concentrate with 989% Zn could be obtained by 7671% lead and 1549% zinc A Process Mineralogy Approach to the Flotation of Complex

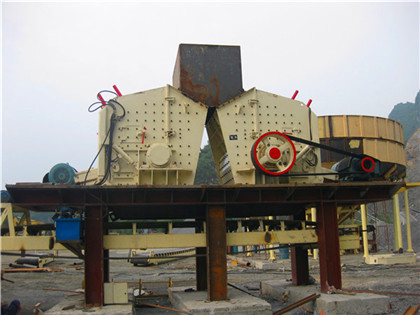

Application Examples of Flotation Machines SpringerLink

About 80% of nonferrous metal ores in the natural world are treated by flotation This section describes the applications of flotation machines in the fields of Liao Jia et al studied and synthesized a new type of flotation agent 750B that is suitable for lead and zinc ore The smallscale flotation contrast test and Promising energystorage applications by flotation of graphite

Optimization of Conditions for Processing of Lead–Zinc

A new collector of Aero 7249 (Shenyang Florrea Chemicals Co, Ltd, Shenyang, China) type was used for the flotation The recovery of valuable components was as follows: Cu, 678%; Zn, In industrial closedcircuit testing, flotation alone was used, which produced a total lead recovery yield of 6771%, and a total silver recovery yield of 8764% In this study, we investigate a lowgrade Sulfidizing Behavior of Complex LeadSilver Ore: A

Sulfidizing Behavior of Complex LeadSilver Ore: A Flotation

In industrial closedcircuit testing, flotation alone was used, which produced a total lead recovery yield of 6771%, and a total silver recovery yield of 8764% In this study, we investigate a lowgrade oxidized lead ore containing noble metal silver, with complex mineralogyIn industrial closedcircuit testing, flotation alone was used, which produced a total lead recovery yield of 6771%, and a total silver recovery yield of 8764% In this study, we investigate a lowgrade oxidized lead ore containing noble metal silver, with complex mineralogySulfidizing Behavior of Complex LeadSilver Ore: A Flotation

Gold Flotation Process, Equipment Mineral Processing

At the same time, we provide various ore flotation process solutions, it also suitable for sulfide silver, zinc, lead, fluorite ore, and copper flotation processing plants The beneficiation plant efficiency and the recovery Quality China High Recovery Mining Processing Equipment Mineral Copper Ore Lead Zinc Froth Cell Flotation Machine With Low Price find quality Ore Beneficiation Equipements, Mineral Separator & Ore Beneficiation Equipements from Gongyi Hengchang Metallurgical Building Material Equipments Plant of China Suppliers China High Recovery Mining Processing Equipment Mineral Copper Ore Lead

Flotation MachineEfficient Separation Solution

Characteristics of Durable JJF flotation machine Wide range of particle size and high recovery rate The large gap between the impeller and the stator is conducive to the mixing and dispersion of air and ore pulp The slurry circulation volume is large, which is beneficial to the mineralization of the ore, reagent and airFleming noted that most of the published generalizations for flotation recovery of lead vanadate minerals before 1950 are not applicable for all lead vanadate ores, in particular, for complex cerussite, vanadinite, and descloizitecontaining ore from Abenab West Mine (Namibia)Mineral Processing and Metallurgical Treatment of Lead Vanadate Ores

High Recovery Rate Lead Ore Flotation Machine Flotation

High Recovery Rate Lead Ore Flotation Machine Flotation Separator, Find Details and Price about Flotation Machine Flotation Separator from High Recovery Rate Lead Ore Flotation Machine Flotation Separator Gongyi Hengchang Metallurgical Building Material Equipments Plant Print This PageSeparation Preferential flotation, zinc suppression and lead recovery Collector: lowgrade xanthate, highgrade xanthate and black drug It is usually separated in alkaline medium Inhibitors: CN , NaCN, KCN, ZnSO4, na2os3, Na2S2O3 Flotation machine in leadzinc ore dressing equipment shall meet the following four basic requirements:Leadzinc Ore Flotation Dasen Mining

Improving Nickel Recovery in Froth Flotation by Purifying MDPI

Before starting the laboratory flotation test, process water pH was adjusted to 95 by lime addition All tests were carried out at a temperature of 20 °C Prior to flotation, the test feed batch was ground in a laboratory mill at 70% solids for 27 min The tests were performed using an Outotec GTK LabCell flotation machine with a 2 LThe aim of this study is to diagnose and optimize a closed multistage gold ore flotation circuit in an operational industrial plant Linear circuit analysis (LCA), a partitionbased model, and a mass balance model using flotation firstorder kinetics are employed to diagnose the current process The result shows that the current circuit Diagnosis and Optimization of Gold Ore Flotation Circuit via

Recovery of lead and barite from the abandoned Ichmoul mine

During flotation of waste rocks from Ichmoul mine, the dosage of Na 2 S varied from 500 to 900 g/t When the amount of Na 2 S added to the pulp increased from 500 to 700 g/t, the recovery of lead varied from 1482 to 1698% (Fig 8 c) However, a decrease (1167%) was observed at a dosage of 900 g/t1213 Application of Flotation Machines for Lead–zinc Ore There are many kinds of flotation machines applied in lead–zinc separation Because of the complex flotation circuit and the small scale of processing, the flotation machines are dominated by small volume equipment, and all the flotation machines are of horizontal configurationApplication Examples of Flotation Machines SpringerLink

Four Points To Improve Tin Ore Flotation Recovery Rate

Attention to these four points can greatly improve the flotation efficiency of tin ore Firstly, please select the appropriate collector and adjust its dosage according to the characteristics of the ore Second, 1 Mixing: The leadzinc minerals are sent to the mixing tank for stirring, and control the pulp concentration at 2535% Add flotation agent, control the pH value of pulp to 911, and stir for 615 minutes 2 Flotation: The process is to suppress zinc floating lead, and then activate zinc According to the floatability of the ores, leadHow to Process LeadZinc Ore by Gravity and Froth Flotation?

High Recovery Rate Copper Mineral XJK Forth Flotation Machine

Flotation machine, in the ore dressing, mainly used for separating copper, zinc, lead, nickel, gold and other Nonferrous metal,can also be used for ferrous, nonmetallic crude and selected After mixing the crushed ore with water and flotation reagent, the ore is mixed into a slurry tank, which is filled with air to form a large number of air bubblesLead Carbonate (Cerussite) Gravity and Flotation Circuit The minus 10 mesh vibrating screen undersize flows to a 12″ x 18″ Duplex Mineral Jig which recovers a high grade lead concentrate The jig tailing passes into a 6 Cell No 15 “SubA” Flotation Machine with 4 cells as roughers and 2 cells as cleaners Sulphidizer, sodiumLead Carbonate (Cerussite) Beneficiation by Gravity & Flotation

Sulfidizing Behavior of Complex LeadSilver Ore: A Flotation Study

In industrial closedcircuit testing, flotation alone was used, which produced a total lead recovery yield of 6771%, and a total silver recovery yield of 8764%38% Recovery rate 74% Manganese beneficiation machines: GZD850×3000 vibrating feeder,PE500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, Highstrength Magnetic drum separators 07 150 TPH Bauxite ore beneficiation plant in Indonesia 10 Best Ore Beneficiation Plants for Sale (with Costs)

Copper Ore Processing Plant Copper Mine Plant With High Recovery

3Pneumatic flotation machine is used to ensure the flotation effect Pneumatic fiotation machine is adopted to obtain good ore beneficiation indicators 4High degree of automation Through the automatic control system, the whole process of ore beneficiation is under monitoring, so the production line can be large scale, automatic and easy to Enhanced performance TON RCS™ flotation machines have made several advances in flotation design and technology Maximize bubbleparticle contact within the mechanism and the flotation tank leads to enhanced performance Effective air dispersion and distribution throughout the cell volume helps in smooth froth surface and removalRCS™ flotation machines TON